The fashion industry is a century overdue for disruption in how we make and buy clothes. But thankfully Crystal Beasley of QCut is up to the challenge.

At first glance, QCut cofounder Beasley‘s past experience wouldn’t lead you to think that the next step on her career path would be making jeans. Most recently, she was a Product Designer at Mozilla and has a background in fine art and computer science.

In a recent interview, she told me that in the midst of that, something inspired her to majorly shake up the fashion industry with 400 sizes of jeans. Surprisingly, the epiphany didn’t come to her in a dressing room, but instead on the streets of Cambodia.

(For more Startup Stories, check out our recent post about a company that crowdfunded its way to Sprayable Sleep and another that’s finding product-market fit for user-read articles.)

The Idea

In October 2013, Beasley took a three-month sabbatical from Mozilla to volunteer with 17 Triggers. “I was there to do behavior change work with non-governmental organizations,” she said. “Things like water sanitation, bringing design principles into helping those kind of programs to essentially deliver better outcomes for people in Cambodia.”

While there, she’d be walking to work or dinner and would pass fields lined with razor wire and filled with protestors being manned by military troops and tanks. These people were workers in the garment industry union, protesting the poor working conditions and wages.

“I, like most people, probably know that your clothes are made in countries where the wages are a lot less, but Cambodia’s is really the bottom of the barrel. Its GDP is about a tenth of its immediate neighbors,” Beasley said.

She couldn’t help but become invested in the controversy that surrounded her. “Being a designer … my first lens that I put on situations is: If I had a magic wand, what would I want the experience of buying apparel to be?” she explained. “And it didn’t take very many dinners and walks and thinking it over to realize that apparel really hasn’t changed much in the last 15 years.”

Disrupting the Market

Unlike many industries, Beasley said that despite the word “fashion” literally meaning current, retailers have stayed anything but. Not in the sense of the cuts of their clothes or keeping up with trends on the front-end, but in how things run behind the scenes.

Besides putting their catalogs online, retailers haven’t done much to change up the way they source, sew and distribute clothes for the past 100 years. Beasley said, “The manufacturing processes are almost completely unchanged.”

Of course, finding brands who are attempting to change the market is difficult, and for the sake of convenience and price we keep buying the same clothes because we believe that they are our only options. But Beasley was tired of leaving well enough alone.

“It seems impossible that a multi-million dollar industry would be producing a product that women universally believe does not work for them,” she said. To start, she knew that a major problem in buying clothes (especially for women) was finding pieces that actually fit properly:

“I validated it by talking to a lot of women. Being a user researcher, a core concept is just to talk to people and find out what their problems are and that’s what led me to making jeans because I found that women all said, ‘I’m hard to fit.'”

When it comes to finding the right fit, jeans are the most difficult equation to solve, so Beasley felt this was the best place to start. She figured that if she got it right with jeans, women would continue to seek out QCut to find their fit.

Finding the Perfect Partner

Given that she didn’t come from a fashion background, after Beasley formulated her idea, she set out to find someone to help her plan for the perfect jeans come to fruition.

She reached out to her entire network to see if they knew anyone who could help. As luck would have it, the Director of Engineering formerly at Mozilla had a connection to Gerald Ruderman, who is basically one of the grandfathers of jeans, having come up with a sizing algorithm for Levi Strauss in the ’90s.

Beasley was certainly not the first person to reach out to Ruderman for help. She said he had people contacting him all the time with their great ideas for jeans. But, after they had a few conversations every couple of months, Ruderman told Beasley about a trade show in Atlanta, and the next day she bought a ticket.

She went to the conference, then she told Ruderman about it. Of course, he was impressed. She explained:

“It was this process of him seeing how serious I was about [QCut] and me quitting my job and sticking with this. A lot of people poke at it and see that it’s hard … and go do something else that’s easier, but I stuck with it.”

Soon after, she flew to Boston to meet with him, and Ruderman offered to be her business partner as Chief Innovator.

Funding Success

To start their funding journey, QCut took to Kickstarter to pitch their made-to-order jeans in 400 sizes. They raised most of their $75,000 funding goal within the first week, eventually surpassing it to the tune of $90,000 when they finished funding in December 2014.

When I asked Beasley about her Kickstarter success, she said that achieving your Kickstarter goal depends on two things: 1) the strength of your idea and 2) your ability to convey that idea.

She said, “You can usually tell how successful your project will be within the first 24 hours because that’s when the project creator sends out tweets and emails to their network.” She added that having great copy and a good video go a long way to communicate your brand and display your commitment and understanding of your idea, but the idea itself is the foundation.

Embracing Slow Fashion

Recently, Beasley did a great exercise in articulating slow fashion by taking an article from The New Yorker on “The Shake Shack Economy” and replacing Shake Shack with QCut to display what she hopes to read about QCut in ten years. The result is kind of awesome and a great articulation of what can come of fashion going the way of food.

The qualities of fast food are almost identical to fast fashion (think H&M and Forever 21): mass production, poor quality, low wages. There’s also, of course, the sacrifice on taste, and Beasley equates good taste in food to the perfect fit in fashion. With slow fashion she said, “It’s made for you. We’re using domestic production. We’re using Italian denim. In the same way that your steak tastes better because it’s grass fed and produced with better quality.”

She said that right now you’re seeing most of the slow fashion movement gaining traction in menswear with tailored suits and shirts, but there are also brands like Modcloth that are incorporating made-to-measure with a focus on plus-sized women — an extremely underserved market. To make this move to slow fashion, Beasley said QCut has to be successful in two major ways:

1. Can we manufacture/deliver the product? To solve this problem in a new, efficient way, “We have to own our own factory because our factory is such a different thing,” she explained. That’s a problem that Ruderman as Chief Innovator is predominantly taking the reins on.

2. How do we make an extraordinary web experience? Beasley said she aims to make a web experience that “convinces women that if they put in this five-minute survey that [QCut] can do a better job than anybody’s ever done making a pair of jeans.” It’s an effort to convince women that this really works, and that’s the problem of which Beasley is in charge.

Testing and More Testing

As with the slow food vs. fast food debate, Beasley said that people want to make smart, sustainable choices but that doesn’t always mean that they’re buying into better quality. Essentially, buying locally-sourced jeans doesn’t always make them a better buy altogether. It doesn’t make them feel good and fit well. So to bring an unbeatable fit factor, they did body scans of 5,000 women and paired their findings with proven statistics to create an original algorithm resulting in their 400 sizes.

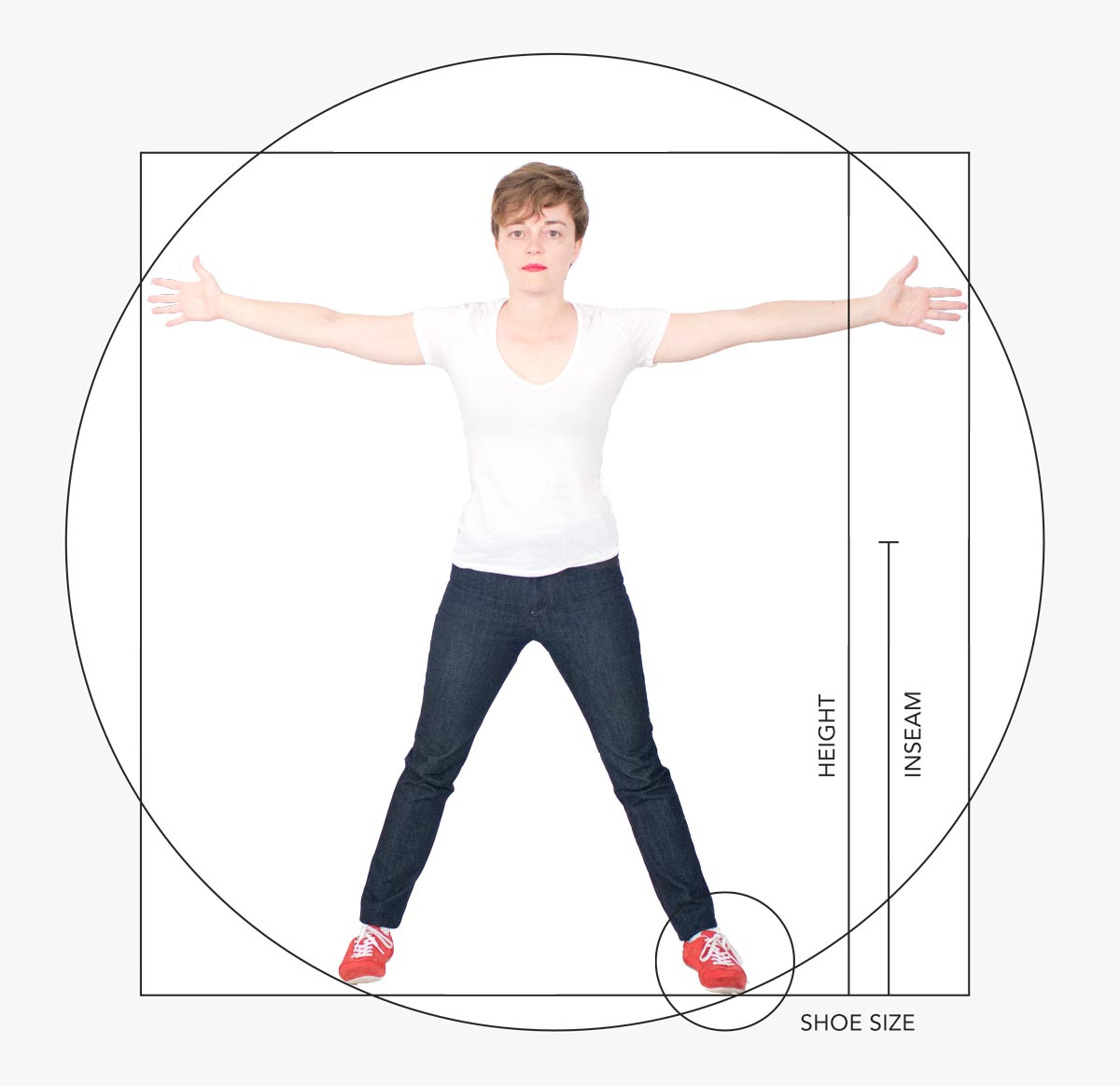

With this algorithm, women just enter these measurements and get a pair of jeans tailored just for them: height, weight, shoe size, bra size and size of their best fitting pair of pants. From there, the numbers you put in make a prediction to the pair of jeans you should be wearing, and that pair gets sent to the factory where it goes through production and then is set to ship to you right away. No jeans are made until you order them and none are just sitting around on the shelves.

Unlike the fear of ordering online to receive an item that doesn’t fit, Beasley wants to change people’s expectations. She said, “Not only when you order things online [can] it fit, it fits you better than anything you’ve bought off of the store racks, because nothing on that store rack was made for you.” If your jeans don’t fit perfectly,you can send them back and get a better-fitting pair for free.

In fact, their model relies so heavily on this algorithm that it’s the first major investment they’re making with their funding. It’s a huge system with a complicated matrix of sizes. They’re going to continue testing it in the coming months on 50 women in several major cities to further score the results and improve the algorithm.

Starting From Scratch

As Beasley mentioned, part of creating this whole new model is building from the ground up with a whole new factory. The system as it currently exists is so archaic that you can’t copy the slow fashion model and tack it onto an existing one. It has to change on a fundamental level.

“It just costs more to make a product that is individually made to order,” she said. “It’s the only way to go to get it to fit. You can’t keep inventory of the number of sizes that it takes to adequately fit all the women well.”

The QCut factory will be built in Portland and, given that much of our clothing in the US is made overseas, Beasley said it will take a lot of training for employees. But it’s also because they’re going to be introducing such a new concept from the process to the set up of the production. They’ll be using Toyota’s Lean Manufacturing Movement, which has already been adopted by most other industries besides sewing.

She explained, “The way that we are sewing is so different than the old-fashioned way of doing it. It’s not any harder to train someone from scratch than it is to unlearn people who already … have habits that are actively wrong.”

The Future of QCut

When I spoke to Beasley, she said they’d completed about 90% of their first round of funding (post-Kickstarter), and they plan to launch the e-commerce site in May so people can get on the waitlist and get a feel for things. In June, they expect to ship out 800 pairs of jeans, mostly to Kickstarter backers. The jeans will retail for $170, around the same price as other premium denim.

She expects to break ground on the factory in Portland (where she lives) in the fall, and it sounds like it’ll be an innovative space with an in-person try-on area and all 400 sizes on the wall. Women can fill out the survey and find their perfect fit in person (in straight or bootcut), then order them to be delivered to their home.

Eventually, Beasley would love to further disrupt the factory model, opening up small regional posts so that QCut merchandise can be more local and optimize shipping times. She said this brings up a lot of questions like, “How small can a factory be?” but that they’ll think about that down the line. They also plan to add more styles after they perfect their model and have at least 90% of women getting the right fit on the first try.

Images were provided by QCut